A 3D printer is an amazing piece of technology that allows us to build almost anything out of almost anything. The difference between a simple machine and a 3D printer is the way it works. A 3D printer takes digital designs and converts them into physical objects, layer by layer. If you’re interested in learning how to program your own 3D printer!

What Is The Best Way To Program a 3d Printer?

Programming a 3D printer is an exciting and rewarding experience. However, it can be tricky at first. To help you get started, we’ve created an easy-to-follow guide that walks you through the entire process.

1. Model Coded In 3d Modeling Software

There are a number of 3D modeling programs available, such as 123D Design and Blender. These tools let you design objects with simple lines and shapes. You can import images or other digital data into these programs to make your designs look more realistic. If you’re interested in designing with 3D modeling software, you can check out our guide to learning 3D modeling.

2. Design Printed

Once your design is completed, it needs to be converted into a file that the printer can understand. The first step in this process is preparing your model for printing. You’ll need to export your design as an STL file.

3. Set up a 3D printer

Next, you’ll need to set up your best 3d printer and load the filament that it uses. You can find out more about how to set up a 3D printer in our guide to 3D printing.

4. Print Model

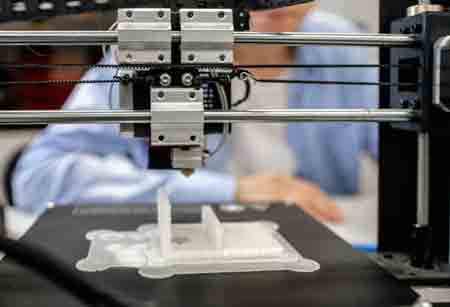

After you’ve set up your printer, it’s time to print! To do this, you need to load the filament into the extruder and turn on your printer. If all goes well, the filament will begin moving through the extruder and your model will begin to take shape.

5. Clean the Print

After the print is finished, you’ll need to clean it. This is important because leftover plastic can clog up your printer and prevent future prints from working properly. To do this, remove the printed object and gently wipe away any excess filament with a cloth or paper towel.

What Are The Advantages And Disadvantages Of Using A Printer For Fabrication Purposes?

Here are some of the advantages and disadvantages of using a 3D printer for fabrication purposes:

Advantages:

-Printing can be very cost-efficient, especially when compared to 3D printing

-Printers are available in many different sizes and shapes.

-Printing can be done at home or in a school lab.

Disadvantages:

-A printer is very time-consuming and not as accurate as traditional manufacturing methods.

-The extruder of the 3D printer does not heat up like traditional manufacturing methods, so it cannot be used to melt materials.

Conclusion

If you’re interested in 3D printing, you’ve come to the right place. Our blog post has a lot of useful information for you, including how to program a 3d printer and a few tips and tricks for getting started. You can find all of this information on our blog post by clicking here.