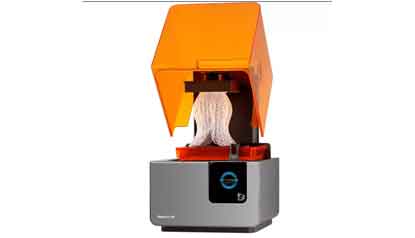

A resin 3D printer is used to create high-quality 3D objects using a layer-by-layer printing process. Resin 3D printers are particularly useful for creating custom prosthetics, car parts, and other objects that need a high level of accuracy and detail a 3D printer can produce parts of any material, including metals. It can also produce a wide variety of complex parts, such as medical devices. Here are some tips before you use a resin printer from Pick3dprinter.

Resin 3D Printing Capabilities

The first thing to know is that resin 3D printers are not capable of creating transparent prints. The layers must be washed, and UV-cured before the print is complete. This requires a considerable amount of time and effort. A quality printer should have a long life span, and it should be able to withstand repeated exposure to UV light for a limited amount of time. A good quality resin 3D printer should have an LCD screen, but this is optional.

Filament and Resin 3D Printers

One of the biggest differences between filament and resin printers is the type of resins they use. While filament-based printers use a variety of materials, resin 3D printers are more expensive. The cheapest options, such as the Formlabs Prusa SL1, are still not cheap. But there are a few prosumer-level options available that are much less expensive. You can also find resin directly on Amazon.

Resin Printing Limitations

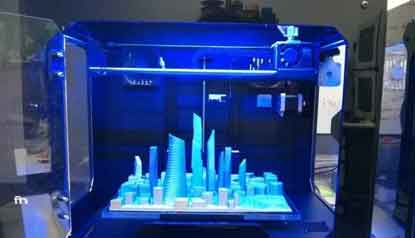

A resin printer is not suitable for large objects. Besides the small build volume, it also has a number of limitations. A large-sized object would require a large photopolymer tank and would take a lot of time and money to manufacture. The process is time-consuming and requires a lot of maintenance. You should also be aware of the limitations and requirements before starting a project.

Resins for 3D Printing

A resin 3D printer uses a light source to cure the resin. This light source helps the resin to harden and form a three-dimensional object. A standard resin is a standard resin. It has a moderate level of mechanical properties and a smooth surface finish. In a resin 3D printer, there are three main types: plastics, polymers, and metals. The plastics that are used for the printing process are called standards.

Uses Different Materials

The resin used in a resin 3D printer is different from those used in the other types of 3D printers. These printers are mostly used for printing models and components. Depending on the application, a resin 3D printer can create both metal and plastic parts. The materials can be mixed to create a wide range of objects. A typical resin is ABS, UDP, and PTFE.

Conclusion

When it comes to resin 3D printers, stereo lithography comes to mind. It was the first technology that was widely used by professionals, and was used for many years before any other 3D printing technology was created. A professional-grade model printer is an example of this. Its price is higher than a professional-grade one. But it is worth noting that the professional-grade models have a larger “Light Delay” to allow for better viewing angles.